In the Spring of 2016 Baptist Health and Accuray donated the Kuka KR-240 surgical robot that was part of their CyberKnife to Newton’s Attic. When looking around for a way to use this terrific resource in a way that would highlight the fun side of robotics we decided on converting it to a 6-axis CNC machine. While contacting various people to get information on this process and put together a parts list we found out that these conversions are typically priced way outside the realm of possibility for a small non-profit organization.

The Kuka coming out of the surgery room

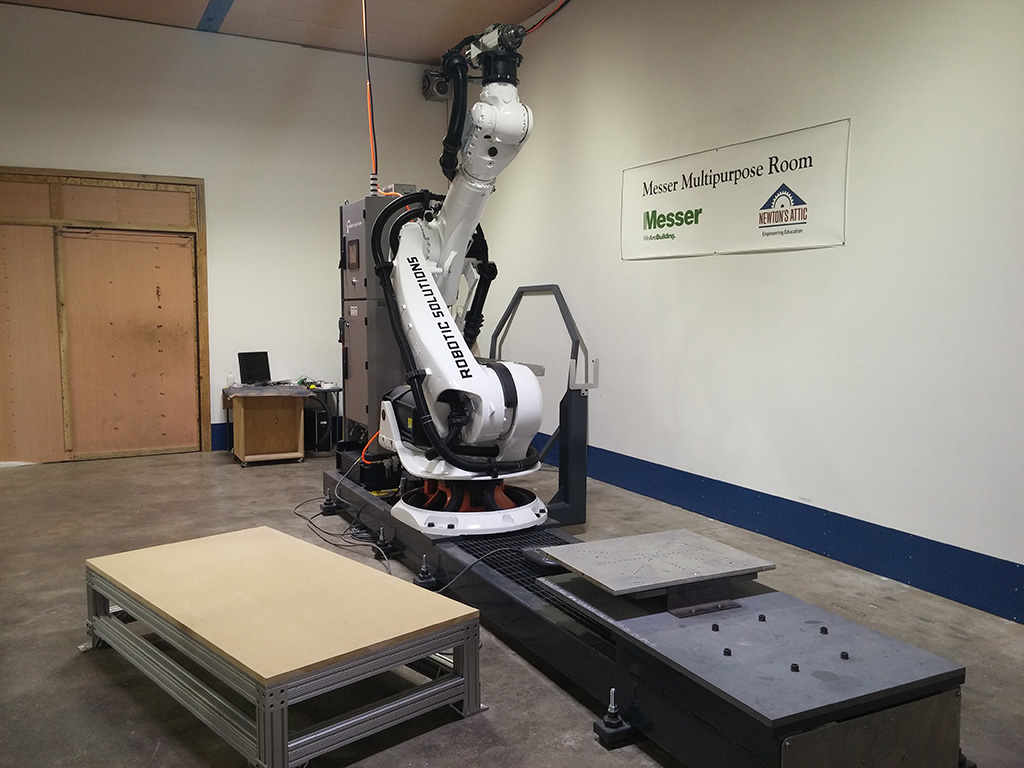

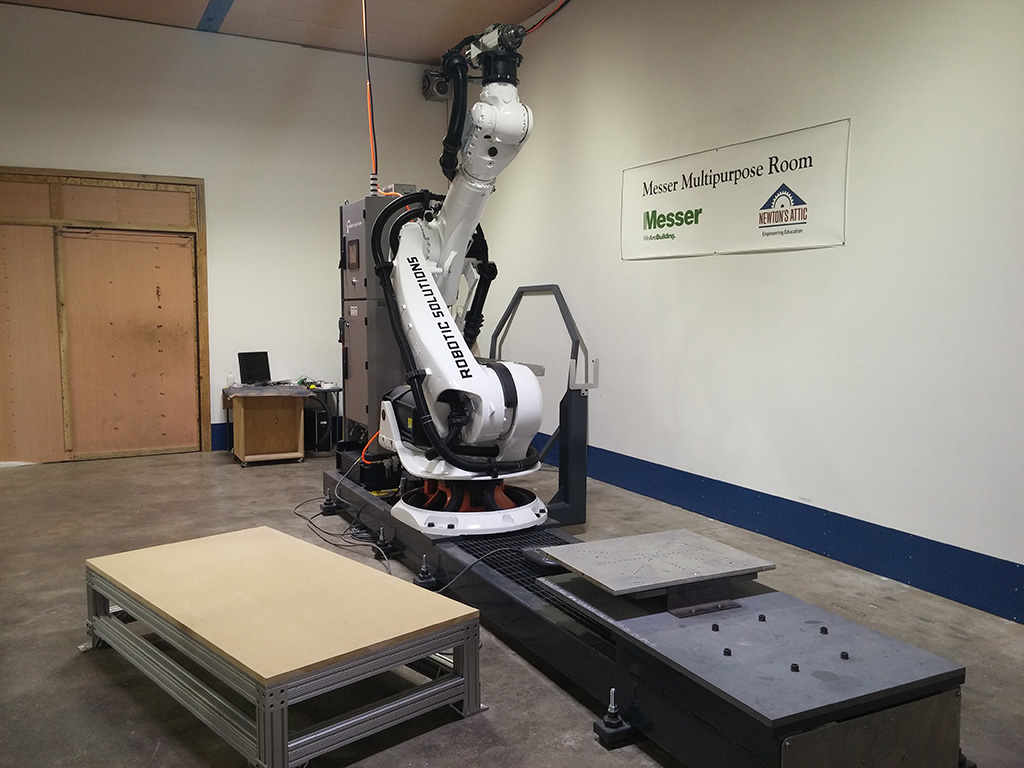

That is when we found Robotic Solutions in Milwaukee, WI. They specialize in doing these conversions and not only had the information we needed but were able to donate equipment, labor, and solicited donations from other companies to bring the cost of the conversion into our budget. We received our training in October 2016, took delivery in November and have been working through increasingly complex projects.

The Kuka as it arrived after CNC conversion

The first test project – A foam rocket